Research assignment – R&D – Energy management of extruders

From September 2024 we have an internship available for a student with a bachelor or master’s in mechanical engineering or Physicist Engineering. In consultation with the department this can be a graduation study. Challenge of this internship is to determine how the energy management in the existing extruder systems is and what kind of solutions are on the market to recover the energy.

Part of the study is also to see how much energy can be won back and what the consequences are for the cost price of the machines. Also the required one time engineering has to be investigated.

The product department R&D Extrusion, Cutters and Flexx is responsible for the development of flexible machines for breaker and body-ply materials for the tire building industry. Using extrusion technology is emerging in this industry. The development of this is an important part of the production process of breakers and body-plies and with the strip wrapping process of car tires.

This department is also responsible for the management and maintenance of the “standard” of our machines in our portfolio. We support other departments such as Sales and Production and we work together with different R&D departments on projects in cross-functional teams. Within R&D Extrusion, Cutters and Flexx we work with 25 professionals. The team consists of Mechanical Engineers, Software Engineers, Electrical Engineers, Process Engineers and a Technical Writer.

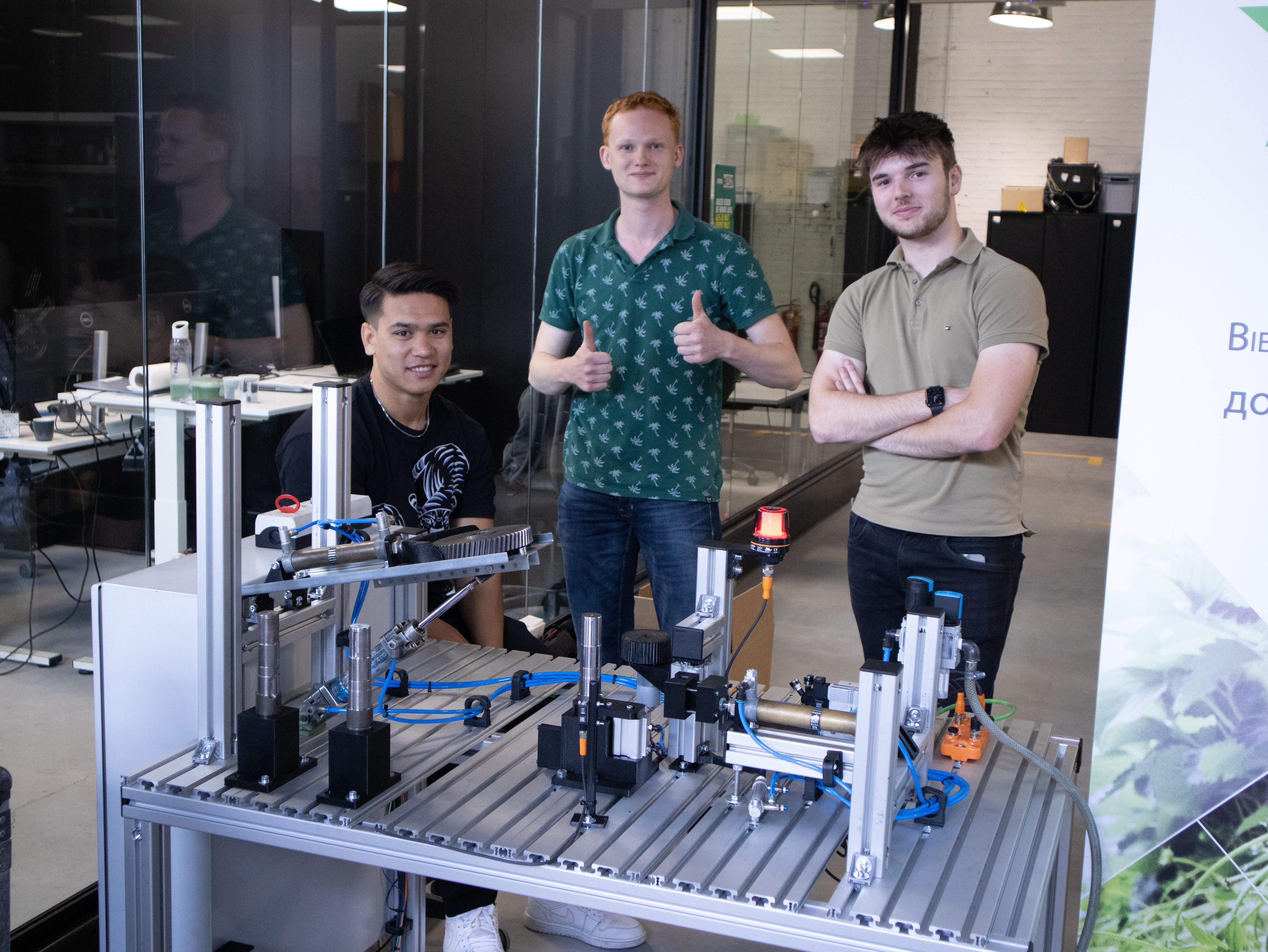

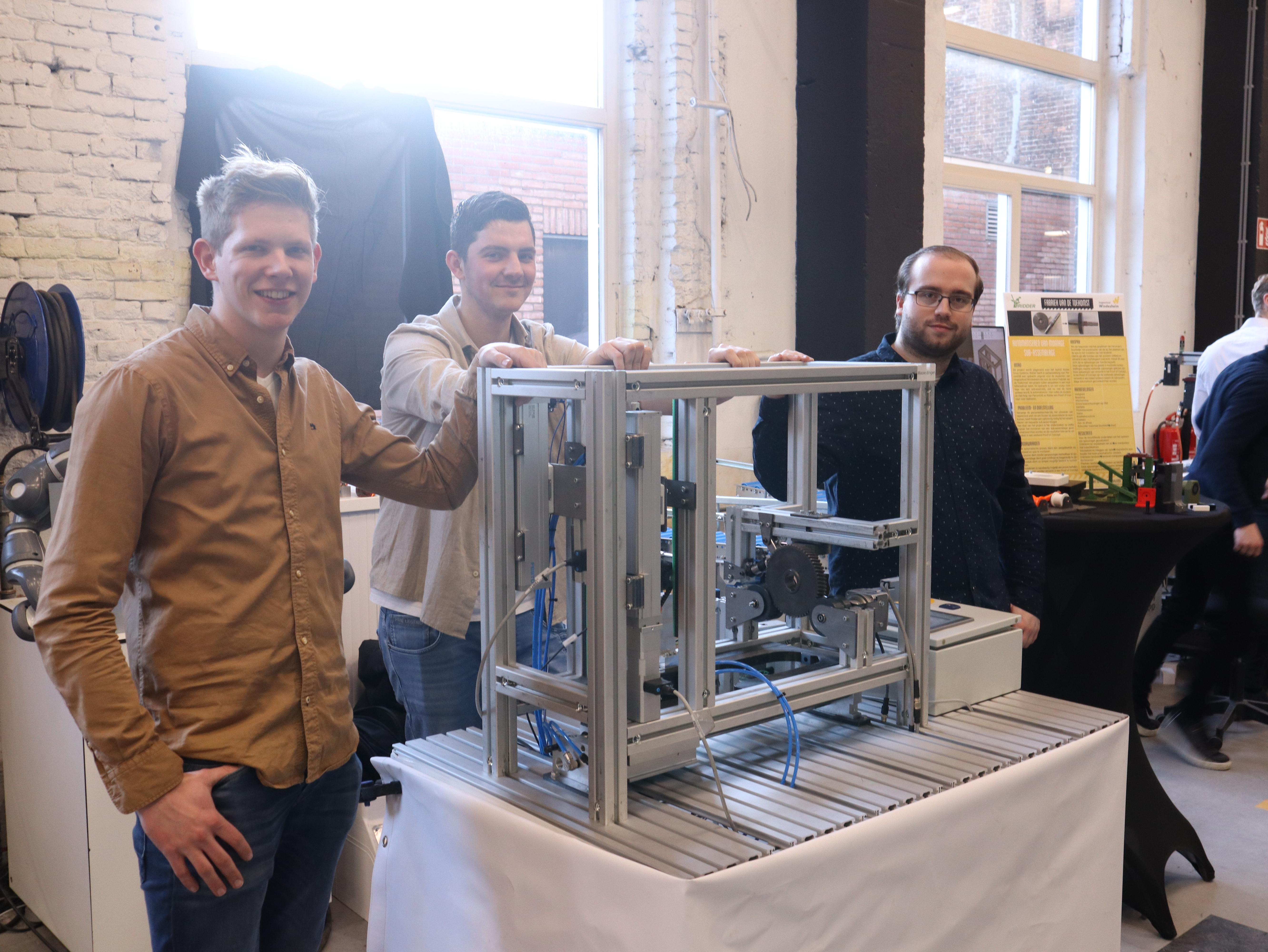

VMI R&D offers an enthusiastic and inspiring working environment.

VMI will provide the required software and ICT requirements (laptop) to work on the problem.

Extruders for the production of rubber components are using a lot of energy. At the start-up of the production line the extruders have to be preheated. During production the screw brings in a lot of heat in the process and then the extruder has to be cooled to keep the process on a constant temperature level. In most of the situations this heat is extracted and blown off outside. In the context of sustainability and saving energy the question is if and how we can recover the energy?

Part of this internship:

- Investigation of the energy management in the extruders during start-up and production

- Investigation of the systems on market to recover energy

- Make concept proposals for alternative solutions (Morphological overview; Kesselring analysis; Reviews etc)

- Investigation of possible energy savings

- Investigation of cost price and one time engineering consequences

- Presentation of the results to the stakeholders

You are given the chance to learn within a nice team for 6 months. Your research will be of added value for the organization. You will receive a compensation for this internship and compensation for travel costs.

Besides our own internship program, you have the opportunity to participate within a Masterclass of Perron038.

These Masterclasses are organized each time by different companies and relate to soft skills, but can for example also be about LinkedIn, project management and job application tips.

VMI is one of the partners at innovation center Perron038 in Zwolle. Various technical companies work together here in the field of Technology and they share knowledge and experiences with each other in an inspiring environment. At the training sessions & Friday afternoon drinks at Perron038 you will also meet students from the other companies in the region. Want to know more about Perron038? Lees verder

With your internship at our company, you make a valuable contribution to our organization. Your input and ideas help us achieve our goals and improve our services.

As an intern, you bring:

- A fresh perspective and new ideas that help us improve our processes

- An opportunity to inspire and motivate our employees with your enthusiasm and energy

- A chance to enrich our culture and values with your unique perspective