Internship assignment – R&D – Rubber properties in extrusion

The objective of this assignment is to understand the effect of time and temperature on the properties of rubber compounds in VMI’s extrusion systems. This will be achieved through a combination of literature research, experiments, and analysis of the results.

The R&D Rubber Process & Tire Technology department of VMI is looking for an intern to complete a research assignment on rubber properties in extrusion.

The R&D department Rubber Process & Tire Technology (RPTT) serves as a research and technology group to support other departments within VMI in topics related to rubber processing and tire technology. In that role RPTT researches current and potential promising topics related to processing rubber compound. It additionally supports product groups to make the right design decisions to shape rubber in the right way in their machines.

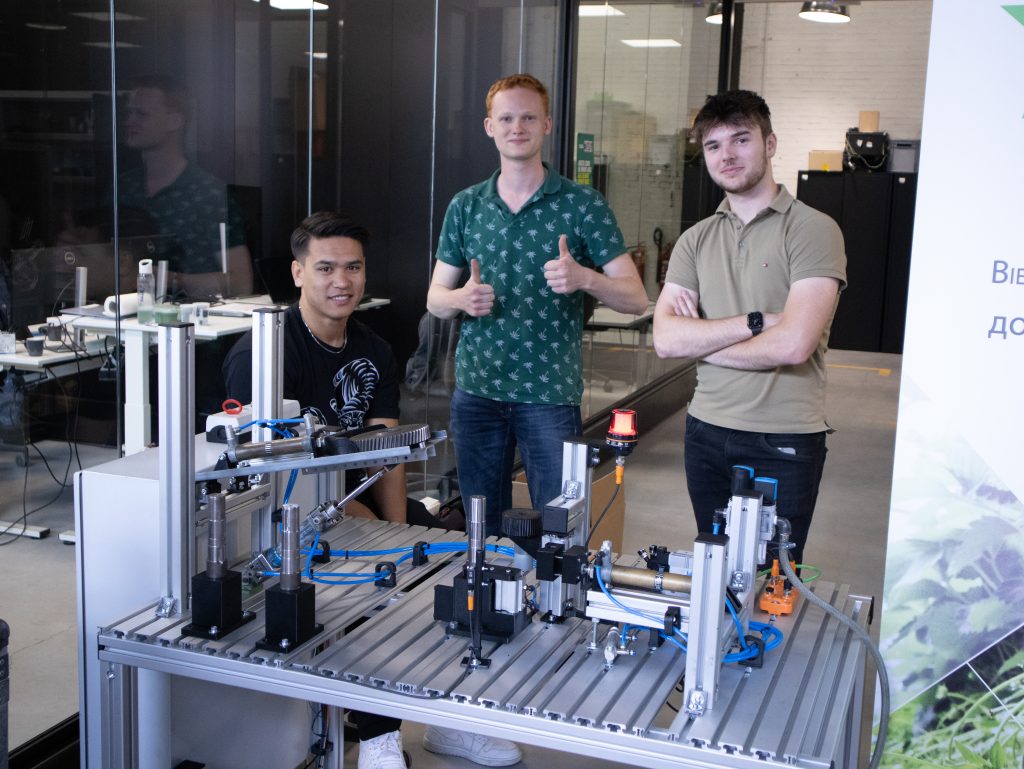

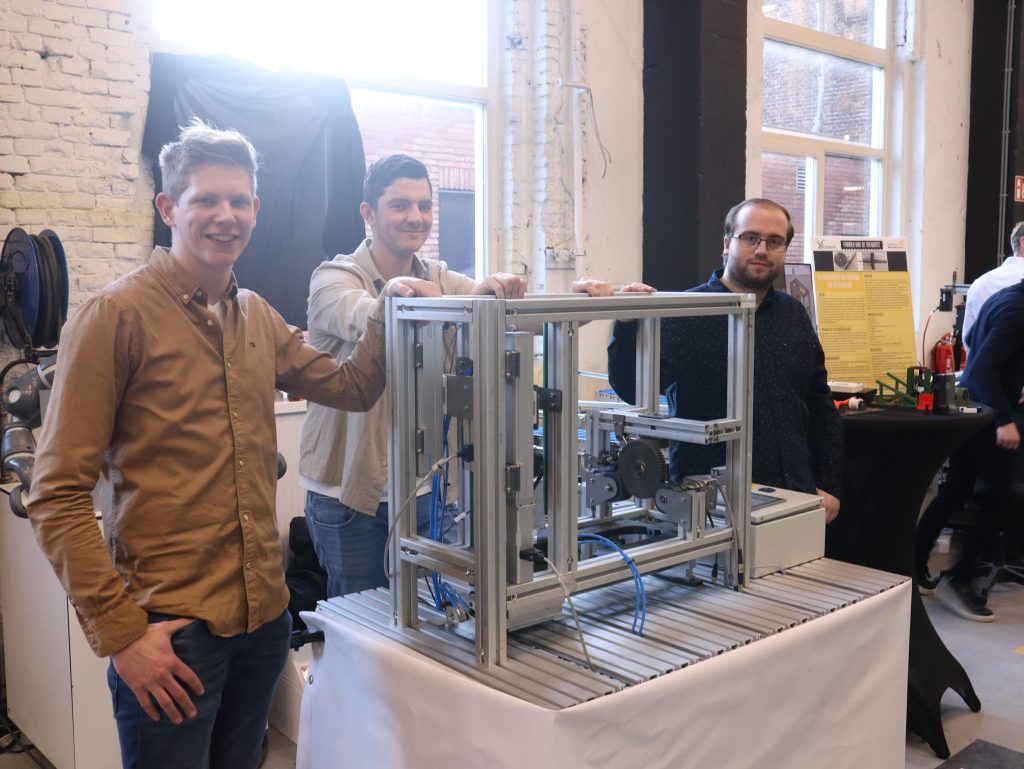

You will be part of a team of 3 rubber process specialists.

A car tire consists of various components, such as the tread and side wall, made from rubbers with unique chemical and mechanical properties. The rubber ingredients are carefully tuned to achieve the desired properties after vulcanization. During the manufacturing process, the rubber compound is vulcanized at high temperatures for some time. During this vulcanization process the rubber characteristics change. VMI uses extrusion systems to produce tire components. If the rubber is heated too much or too long in this process, the characteristics might change too much influencing the performance of the final tire in a negative way.

As an intern at VMI, you will study the impact of different extrusion systems of VMI on key rubber compound characteristics.

You will work on the following activities:

- Literature review on the effect of temperature and time on rubber compound properties;

- Creating an overview of the different VMI extrusion processes that thermally load the rubber compound;

- Understanding the working principle of a Moving Die Rheometer (MDR) that is used to measure key characteristics of rubber compounds during vulcanization;

- Preparing and performing multiple trials on extrusion systems to collect samples that have a different thermal loading history to be analyzed with the MDR;

- Define warning levels or guidelines to prevent compound vulcanization in our extrusion systems;

- Document assignment in a report.

- You are an hbo/wo student in Mechanical Engineering, Polymer engineering or Chemical Engineering;

- You are currently in the final year of your studies;

- You are looking for an internship of 40 hours per week. For this internship, it is possible to be working partly at home on the assignment;

- You are creative, proactive, solution-oriented, analytical and research-oriented person.

We give you the opportunity to join a cozy team for six until nine months. You will have the opportunity to carry out challenging research in which you can add real value to the organization. For this internship you will receive an internship allowance that you can expect from a leading company and a travel allowance.

In addition to our own internship program, you will have the opportunity to participate in a Master Class at Perron038.

These Masterclasses are organized each time by different companies and relate to soft skills, but can for example also be about LinkedIn, project management and job application tips.

VMI is one of the partners at innovation center Perron038 in Zwolle. Various technical companies work together here in the field of Technology and they share knowledge and experiences with each other in an inspiring environment. At the training sessions & Tuesday afternoon drinks at Perron038 you will also meet students from the other companies in the region. Want to know more about Perron038? Read more

With your internship at our company, you make a valuable contribution to our organization. Your input and ideas help us achieve our goals and improve our services.

As an intern, you will bring:

- A fresh perspective and new ideas that help us improve our processes;

- An opportunity to inspire and motivate our employees with your enthusiasm and energy;

- a chance to enrich our culture and values with your unique perspective.

Interested?

Have you become interested and do you think you are the student we are looking for?

Then apply immediately!

A screening test may be part of the application procedure.